Unique Tips About How To Build Linear Motor

This video is an overview of my linear motor build.

How to build linear motor. The inner rod of the actuator is basically a threaded rod now if you are using a cordless drill as i have decided to do in the end then you could just cut it to the correct length with enough to fit. How to make a powerful electric actaultor , linear motor , electric cylinder related videos1. (1) make two iron wires straight as possible as you can.

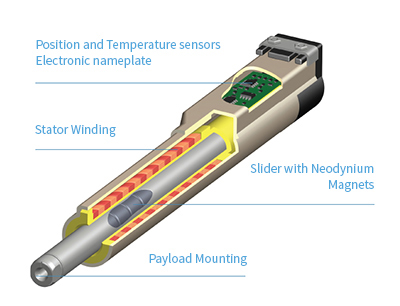

This systems uses two or more rotary cogs or. This led me to thinking about what it would take to build my own linear actuators. By powering the dc motor, the arm moves out linearly;

A linear actuator functions very simply. How to make dc motor at home , homemade electric motor easy htt. Mark the position for the motor mount bracket, drill pilot holes and screw it to the base.

Industrial linear motors offer design engineers the possibility of constructing machines in new ways. Mark the position for the bearing support. Only the lazy don't make such a motor

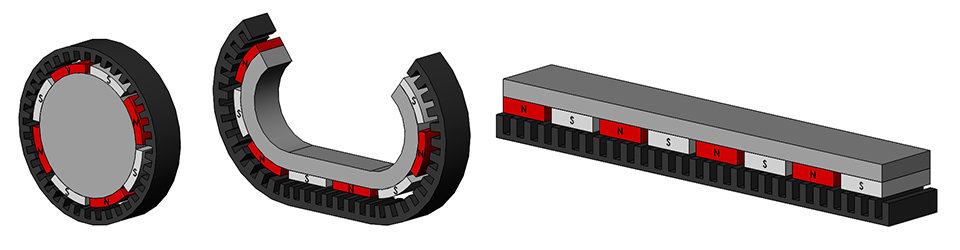

Classic examples of this include conveyor belts and tank tracks. Establishing the system orientation pick the orientation of your application: (3) the distance between two wires is about 4 cm.

Linear motion translates rotational motion into motion across a flat plane. Fast, simple, and flexible, linear motors are easy to install.